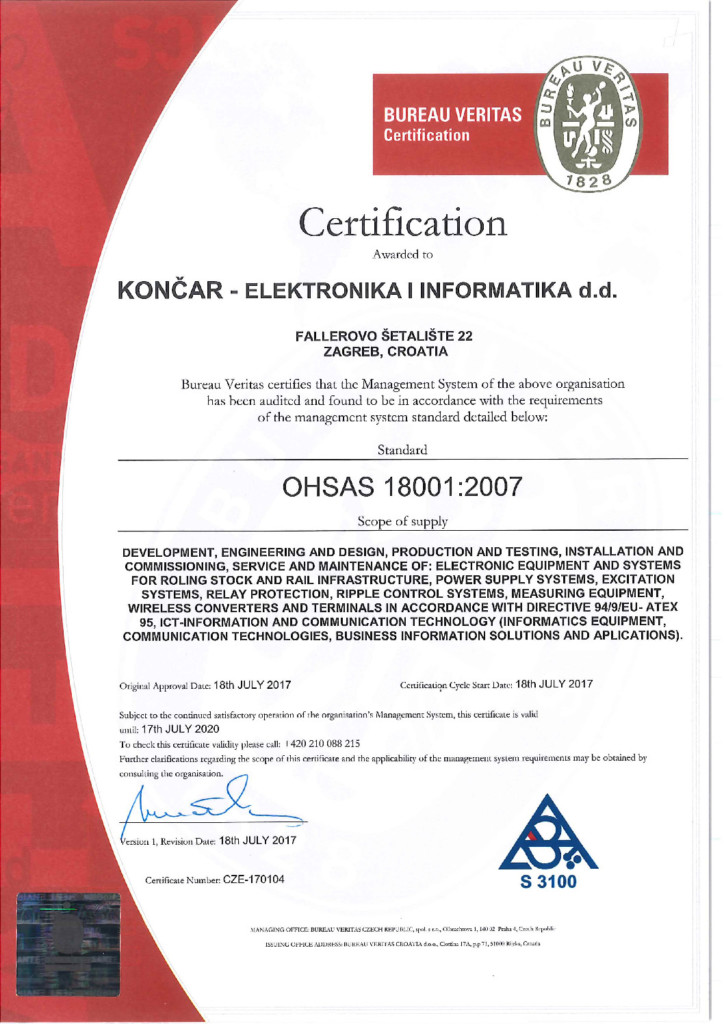

KONČAR – Electronics and Informatics proud holder of the OHSAS ISO 18001:2007 certificate

Since last week, KONČAR – Electronics and Informatics became a proud holder of the OHSAS ISO 18001:2007 certificate, globally recognized Health and Safety Management System. This is fully in line with the philosophy of the company and the group to which it belongs, oriented at all times towards the individual with the utmost conviction and responsibility. The audit was carried out last month by experts from Bureau Veritas, and now an official certificate was issued and is valid for the next three years, of course, with mandatory annual control.

Improving business quality in KONČAR – Electronics and Informatics is permanent, as well as the determinant and long-standing practice and because of that, we always strive to be aligned with the latest ISO standards. The first step was made twenty years ago when we were awarded with first certificate for the Quality Management System (ISO 9001), and since 2003 we were certificated according Environmental Management requirements (ISO 14001).

The development of the management system has shown the need to validate and integrate the Health and Safety Management System into the already introduced Quality Systems and Environmental Protection and has been successfully acknowledged by this certificate. The Health and Safety Management System is fully in line with the OHSAS ISO 18001: 2007 standards.

We will continue to work actively to keep track of all relevant professional standards and meet the highest demands and thus provide the highest value to our customers and our employees.

Power supply system for HPP Ozalj 1

Rreconstruction, testing and temporary commissioning of the power supply system in the hydro power plant Ozalj 1 was completed at the beginning of the month. The task was contracted as part of a comprehensive reconstruction of the power plant: primary and secondary electrical equipment, mechanical equipment and necessary architectural and construction works.

Hydro power plant Ozalj 1 is the second oldest hydropower plant in Croatia, it was built and put into operation in 1908 to supply Karlovac public lighting system and named “Munjara grada Karlovca” (Lightning factory of the city of Karlovac). It significantly contributed to the development of industry in Ozalj, Karlovac and Duga Resa in the years that followed.

This historically valuable facility is protected cultural heritage, under the supervision of the Directorate for the Protection of Cultural Heritage and the Ministry of Culture of the Republic of Croatia, which means that all works must be coordinated and realized with a special care.

The scope of the contract included the reconstruction of the 110 V DC supply system and delivery of a new uninterruptable 230 V AC power supply system. The reliability of the DC system was significantly increased by the incorporation of a new modular, redundant rectifier cabinet type KONIS-B 110 V, 60 A. Reliable AC power supply was realized with Modular UPS type Megaline rack. The final commissioning will be done upon completion of the reconstruction of other equipment.

Power supply system for TS 220/110/35 kV Međurić

The substation computer, technical protection and telecommunications equipment in the SS 220/110/35 kV Međurić are important and sensitive equipment that requires uninterruptible and stable AC voltage for its power supply.

The new system KONIS-BI 110 V, 80 A / 230 V, 11 kVA is designed according to the principles of the industrial UPS system, ensuring the highest level of reliability and availability.

Standard modular rectifiers and inverters are used, configured according to n + 1 redundant parallel operation principle. Other basic components of the system are: battery, static by-pass switch, manual by-pass switch, control unit and AC distribution panel.

At the end of March, Končar Inem contracted the design, production and assembly of equipment and commissioning. The design and the production of the equipment have been completed in a very short time. The quality control of the equipment was successfully carried out in the test station at the end of May in the presence of an investor’s representatives. Works on the transformer station starts according to plan, early June.